Videos

Simplemente las mejores brocas helicoidales de larga duración para metal

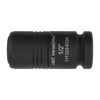

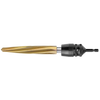

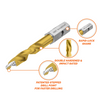

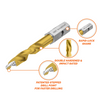

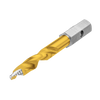

Las brocas de cobalto VersaDrive® son brocas de cobalto al 8 % de calidad superior con estrías completamente rectificadas, punta dividida de 135° y revestimiento de titanio para una perforación más rápida y un desgaste reducido.

Adecuada para uso de fabricación pesada, esta broca de cobalto también se puede utilizar para perforar acero inoxidable, acero dulce, hierro fundido y una amplia gama de otros materiales estructurales.

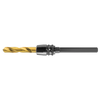

Las brocas VersaDrive® tienen un vástago hexagonal antideslizante patentado adecuado para usar en cualquier portabrocas estándar de 1/2” para taladros inalámbricos o de pistola o para usar con un adaptador VersaDrive® Rapid Lock para usar en una amplia gama de herramientas eléctricas como taladros magnéticos.

Beneficios del producto

- El diseño de ranura rectificada con precisión proporciona una fácil limpieza de virutas

- Acero para herramientas con 8 % de cobalto para una larga vida útil y resistencia con punta dividida de 135º para un arranque fácil y alta precisión

- El recubrimiento de nitruro de titanio de grado industrial reduce la acumulación de calor y el quemado.

- Úselo en caso de impacto para evitar el peligroso contragolpe provocado por herramientas rotativas portátiles

- Diseño de vástago hexagonal de alta resistencia para un funcionamiento seguro y antideslizante.

- Resultados de calidad en aceros inoxidables e Inox. Se recomienda aplicación rotativa.

- El vástago patentado VersaDrive y los adaptadores modulares brindan una flexibilidad inigualable en el lugar de trabajo

- Resistente a impactos gracias al proceso de endurecimiento dual: permite una velocidad hasta 15 veces más rápida que los métodos tradicionales

Guía rápida

- Vida útil y rendimiento óptimos cuando se utilizan con taladros de pistola rotativos

- Se pueden utilizar hasta 3/8" en llaves de impacto y destornilladores de impacto para un rendimiento de corte rápido

- Adecuado para materiales más duros como el acero inoxidable cuando se utiliza a RPM reducidas

- Utilice la lubricación adecuada y las RPM correctas para lograr una larga vida útil de la herramienta.