Videos

15 veces más rápido que tocar con la mano

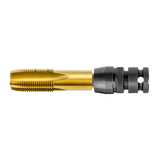

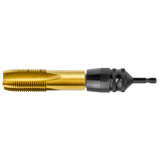

Los machos de roscar VersaDrive® ImpactaTaps son la primera y única gama de machos de roscar que pueden accionarse con llaves de impacto y destornilladores de impacto, y proporcionan un rendimiento al menos 15 veces más rápido que el roscado a mano.

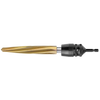

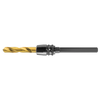

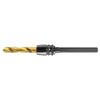

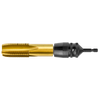

Con una geometría de corte de doble filo especialmente diseñada, el proceso de endurecimiento dual con revestimiento de titanio proporciona una solución fantástica para perforar agujeros en acero.

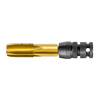

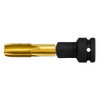

Los machos de roscar VersaDrive® ImpactaTaps tienen un vástago hexagonal antideslizante patentado apto para usar en cualquier portabrocas estándar de 1/2” para taladros inalámbricos o de pistola (hasta M10) o para usar con un adaptador VersaDrive® Rapid Lock para usar en una amplia gama de herramientas eléctricas, como taladros magnéticos. Incluso se pueden usar a mano en una llave de tubo.

Beneficios del producto

- Acción rompevirutas de impacto para una evacuación eficaz de las virutas

- Geometría de corte única de doble punta con ranuras rectificadas

- Cree agujeros roscados internos con rapidez y precisión

- Limpie y repare rápidamente roscas internas dañadas o sucias

- El recubrimiento de nitruro de titanio de grado industrial reduce la acumulación de calor y el quemado.

- Úselo en caso de impacto para evitar el peligroso contragolpe provocado por herramientas rotativas portátiles

- Diseño de vástago hexagonal de alta resistencia para un funcionamiento seguro y antideslizante.

- Resistente a impactos gracias al proceso de endurecimiento dual: permite una velocidad hasta 15 veces más rápida que los métodos tradicionales

Guía rápida

- Para un rendimiento más rápido, utilice llaves de impacto y destornilladores de impacto.

- Compruebe el par mínimo requerido

- El roscado de acero inoxidable requiere un mayor par de impacto

- Utilice la lubricación adecuada y las RPM correctas para lograr una larga vida útil de la herramienta.