Videos

EL TALADRO DE PRIMER PASO OPTIMIZADO PARA USAR CON LLAVES DE IMPACTO Y DESTORNILLADORES DE IMPACTO, QUE PERMITE AL USUARIO CREAR AGUJEROS EN SEGUNDOS

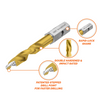

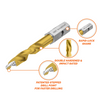

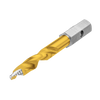

Con un diseño de flauta en espiral con punta de perforación de arranque automático para una perforación rápida y suave con un taladro rotatorio o una llave de impacto y una capacidad de perforación de 3/16" (5 mm) de espesor líder en el mercado.

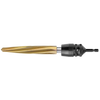

Los taladros escalonados VersaDrive tienen un vástago hexagonal antideslizante patentado adecuado para usar en cualquier portabrocas estándar de 1/2” para taladros inalámbricos o de pistola, o para usar con un adaptador VersaDrive Rapid Lock para usar en una amplia gama de herramientas eléctricas, como taladros magnéticos.

Beneficios del producto

- Diseño de flauta en espiral con un espesor de 3/16" (5 mm) líder en el mercado y marcas de tamaño en cada paso

- Ángulo de punta dividida de 118º para un inicio de orificio fácil y precisión de pilotaje

- El recubrimiento de nitruro de titanio de grado industrial reduce la acumulación de calor y el quemado.

- Úselo en caso de impacto para evitar el peligroso contragolpe provocado por herramientas rotativas portátiles

- Diseño de vástago hexagonal de alta resistencia para un funcionamiento seguro y antideslizante.

- Resultados de calidad en aceros inoxidables e Inox. Se recomienda aplicación rotativa.

- El vástago patentado VersaDrive y los adaptadores modulares brindan una flexibilidad inigualable en el lugar de trabajo

- Resistente a impactos gracias al proceso de endurecimiento dual: permite una velocidad hasta 15 veces más rápida que los métodos tradicionales

Guía rápida

- Para un rendimiento más rápido, utilice llaves de impacto y destornilladores de impacto.

- Adecuado para acero inoxidable y materiales más duros si se utiliza a bajas RPM.

- Utilice la lubricación adecuada y las RPM correctas para lograr una larga vida útil de la herramienta.

- Excelente vida útil y rendimiento cuando se utiliza con taladros de pistola rotativos o taladros de columna

- Follow guidelines to set correct RPM speed. Incorrect RPM can lead to poor life or tool breakage

- Apply firm, steady feed pressure throughout the cut

- Avoid lateral movement or tilting which can cause damage to the tool

- Ensure regular application of quality cooling lubricant, especially when drilling thick or hardened materials.

- Hardened or heat-affected materials may require higher torque, reduced RPM and feed rates and extra coolant

- When drilling into box section ensure the tip of the Step-Drill is not contacting the far side of the box section at the same time it is drilling the outside wall. This may cause breakage to the tool.

Use the tables below to identify the recommended Nm or Ft Lbs of Torque or RPM for your hole size and material.

Use Nm or Ft Lbs of Torque for drilling with Impact tooling.

Use RPM for drilling with Rotary tooling.

N.B. Impact Torque recommendations are the minimum required and for most applications additional torque is a benefit. For Impact applications where Torque values available do not offer an exact match to the table below select the closest available torque setting ABOVE the recommendation.

VersaDrive tooling can be used with a wide range of adapters that allow the products to be used across a variety of drive tools depending on the application required.

Below you will find the recommended adapters for the VersaDrive 505020 Step Drill.

- Identify the torque range (for the cutting tool) required using the data sheet in question 2. (Example M12 in 12mm plate – Guide torque 320Nm)

- Identify the torque range on your impact wrench or impact driver

- Look up model number to see torque range

- Check if there are speed/torque settings on the tool - Example

- Select the closest torque setting on the impact wrench/impact driver ABOVE the torque recommendation

(this is for the following 2 reasons)

- Higher torque will only be used on demand

- Too low torque will lead to the tool jamming or even snapping as the flutes stop cutting and the torque transfers to the tool