Videos

Mantenga el trabajo en marcha cuando un orificio de conexión sea de tamaño insuficiente

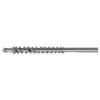

Los escariadores VersaDrive® tienen un vástago hexagonal antideslizante patentado adecuado para usar en cualquier portabrocas estándar de 1/2” para taladros inalámbricos o de pistola o para usar con un adaptador VersaDrive® Rapid Lock para usar en una amplia gama de herramientas eléctricas como taladros magnéticos.

No se recomienda utilizar escariadores VersaDrive® para perforar orificios cortados con láser o plasma. Los orificios afectados por el calor se pueden agrandar utilizando el escariador VersaDrive® con un taladro magnético de baja velocidad.

Beneficios del producto

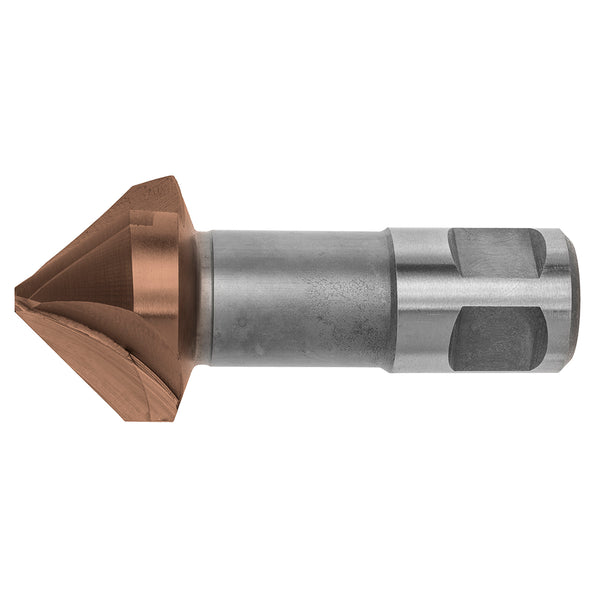

- Diseño de precisión de 6 flautas para un corte suave.

- Diseño de corte de borde para agrandar el orificio, brindando resultados mucho mejores que una broca.

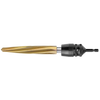

- El recubrimiento de nitruro de titanio de grado industrial reduce la acumulación de calor y el quemado.

- Úselo en caso de impacto para evitar el peligroso contragolpe provocado por herramientas rotativas portátiles

- Diseño de vástago hexagonal de alta resistencia para un funcionamiento seguro y antideslizante.

- Resultados de calidad en aceros inoxidables e Inox. Se recomienda aplicación rotativa.

- El vástago patentado VersaDrive y los adaptadores modulares brindan una flexibilidad inigualable en el lugar de trabajo

- Resistente a impactos gracias al proceso de endurecimiento dual: permite una velocidad hasta 15 veces más rápida que los métodos tradicionales

Guía rápida

- Para un rendimiento más rápido, utilice llaves de impacto y destornilladores de impacto.

- No se recomiendan los escariadores de impacto para orificios cortados con llama o plasma. Utilícelos con un taladro magnético.

- El escariador debe girar antes de comenzar el corte y se debe utilizar una presión de avance constante durante el corte.

- Para materiales con un espesor superior a 20 mm se recomienda el uso de escariadores ImpactaMag.