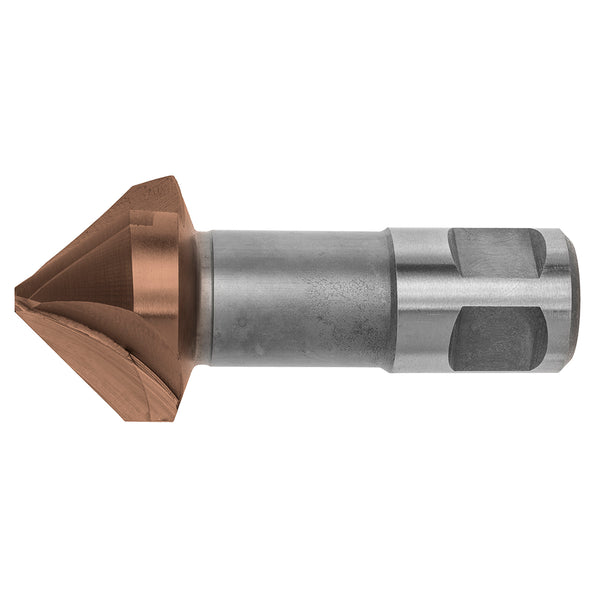

Carbidemax ULTRA Tooling

HMT have developed a generation of ULTRA cutting tools for use in the most challenging applications.

Specialist high performance range of tooling for wear plate, armor applications and rail track applications.

Premium, long-life tooling for use in the most challenging applications.

The specialist ULTRA coating is proven to significantly increase tool life, making these tools the ideal solution in situations requiring high performance durability, prolonged use or machining extremely hard materials.

They are produced from premium grade materials and coated using a range of state of the art, high-temperature surface coatings.

Rated for use on materials such as

HARDOX - CREUSABRO - ABRO - RAEX

STRENX - BISALLOY

CarbideMax ULTRA Benefits

- Capable of providing a service life up to 10x longer than uncoated TCT tools

- Use for increased durability

- Cuts material 5x harder than S275 Structural Steel

- Use on Stainless Steel

- Perfect for use on heavy equipment & machinery

- Use with Biocut Blue & SpeedLube Lubricants

- Use on wear plate & Armour plate

Please Note: The extreme hardness and resistance of wear plate makes machining it extremely challenging. Good results are dependent on the right setup - including high torque/slow speed, geared Magnet Drills, like the VersaDrive Series, and ample lubrication - BioCut Blue cutting fluid when broaching or Speedlube Aerosol spray when countersinking.

Using an incorrect or poorly maintained Magnet drill with unstable drilling operation, poor magnet hold, excessive pressure or inadequate lubrication is likely to result in rapid tool failure.

Even with high tech tooling, successfully machining Wear plates is challenging with little or no margin for error. It not only requires the correct setup but also experienced operators with the time necessary to proceed with caution.