Videos

THE FIRST STEP DRILL OPTIMISED FOR USE WITH IMPACT WRENCHES & IMPACT DRIVERS, ALLOWING THE USER TO CREATE HOLES IN SECONDS

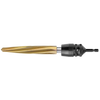

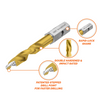

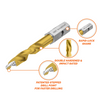

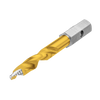

Feature a spiral flute design with self-starting drill tip, for fast, smooth drilling with a rotary drill or impact wrench and market-leading 5mm thick drilling capacity.

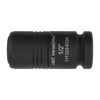

VersaDrive® Step Drills have a patented non-slip, Hex shank suitable for use in any standard 1/2" drill chuck for cordless or pistol drills or used with a VersaDrive® Rapid Lock adapter for use in a wide range of power tools such as Magnetic Drills.

Electrical Step Drill

Cutting diameters:

4, 6, 8.5, 10.5, 12.5, 14.5, 16, 18.5, 20.5, 23.5, 25, 30.5, 32.5mm

Product Benefits

- Market leading 3/16" (5mm) thickness, spiral flute design and size markings at each step

- 118º split point angle for easy hole start & pilot accuracy

- Industrial grade Titanium Nitride coating reduces heat buildup and burn-out

- Use on Impact to prevent dangerous kickback caused by handheld rotary tools

- Heavy-duty hex shank design for secure non-slip operation

- Quality results on stainless steels and Inox - rotary application recommended

- VersaDrive patented shank and modular adapters provide unbeatable jobsite flexibility

- Impact-rated due to dual hardening process - allows up to 15X faster speed than traditional methods

Quick Guide

- For fastest performance use on Impact Wrenches & Impact Drivers

- Excellent life and performance when used with rotary pistol drills or drill presses

- Suitable for stainless and harder materials if used at low RPM

- Use appropriate lubrication and correct RPM to achieve long tool life